Sponsored article

As the world continues to steer towards more sustainable energy solutions, the role of Lithium-Ion batteries becomes increasingly crucial. This article offers an enlightening journey into the world of European Lithium-Ion battery production, highlighting the intricate manufacturing process, its environmental repercussions, and the tremendous benefits it poses to the economy and infrastructure. Discover how Europe is pioneering in producing these powerhouses, shaping a sustainable energy future.

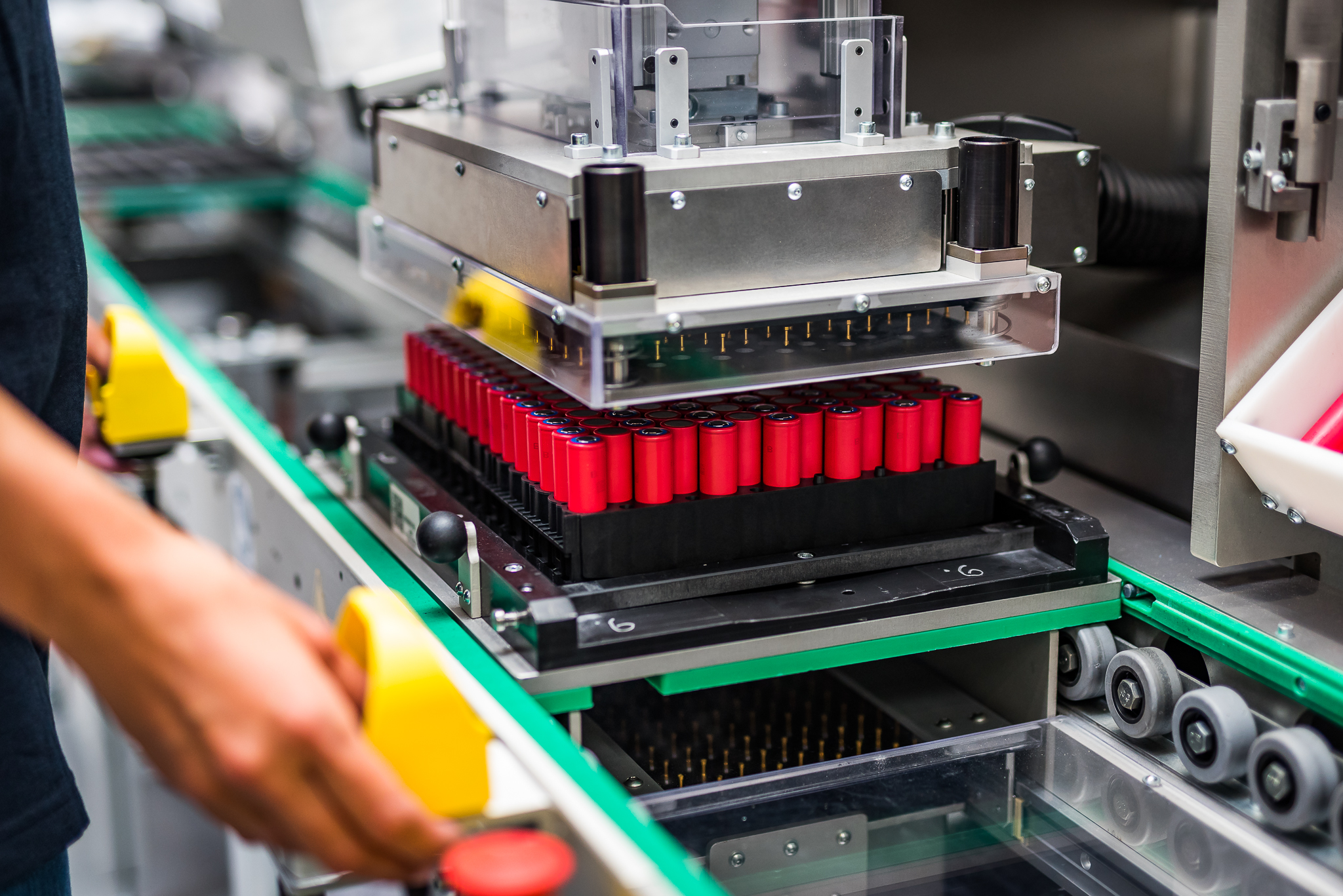

The manufacture of Lithium-Ion batteries is a complex, thorough production process that commences from the extraction of raw materials. Understanding these procedures underscores the dedication to quality and efficiency that sets apart a notable lithium battery manufacturer in Europe like Johnson Matthey Battery Systems. They ensure that each step in the production journey is precisely executed to yield high-quality and reliable Lithium-Ion batteries.

From sourcing the necessary components such as lithium, cobalt, nickel, and manganese, to the assembly, testing, and certification, the intricacy of each stage is significant in the final output. Johnson Matthey’s well-mastered production process, therefore, ensures their standing as a leading Lithium-Ion battery manufacturer in Europe, geared towards sustainability and innovation.

The environmental impact of Lithium-Ion battery production is a crucial point to consider, as energy-intensive manufacturing processes often lead to a significant carbon footprint. Yet, with sustainable practices, the European Lithium-Ion battery industry strives to minimize environmental harm effectively. Eco-conscious manufacturing techniques reduce both energy consumption and greenhouse gas emissions, demonstrating a commitment to broader sustainability goals.

Moreover, the industry also invests in innovative recycling methods to respond to the environmental challenge. This approach not only reclaims valuable materials but also abates the natural resource depletion and potential toxic waste associated with disposal of Lithium-Ion batteries. Thus, considering the environmental implications, the modern-day Lithium-Ion battery industry is tailoring its strategies towards an environmentally-friendly future.

The surge in production of European Lithium-Ion batteries presents undeniable economic benefits for the continent. This ramp up in manufacturing has spurred employment growth in the industrial sector, consequently stimulating various other sectors of the economy indirectly. Investment in these energy-efficient powerhouses underpins Europe’s commitment to building a greener future.

Furthermore, the advantages cascade to infrastructural development. The production of European Lithium-Ion batteries necessitates sophisticated and modern facilities, encouraging infrastructural advancements. These high-capacity batteries play a paramount role in the energy sector, fostering innovation and propelling Europe’s transition towards renewable power sources. Thus, the European Lithium-Ion battery production exerts a far-reaching impact on society, ushering in an economically robust and ecologically favorable era.